Tesla Describes System of Impact Attenuation in Structural Battery Pack in Patent Application

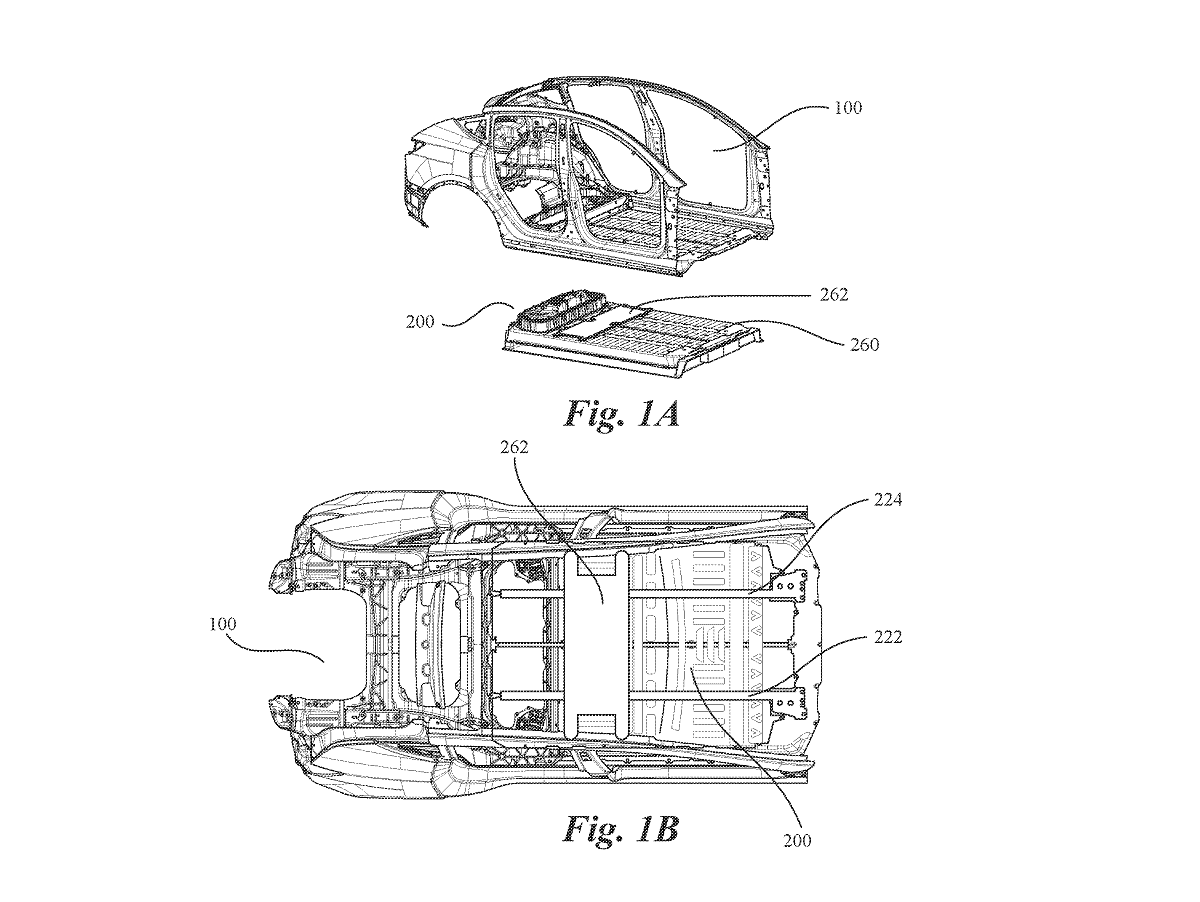

After the start of production of 4680 battery cells, Tesla began using them in structural battery packs that became part of the car’s main structure. The company describes a system of impact attenuation in its structural battery pack in a patent application filed in January 2023.

Background

Battery cells are needed to manufacture electric vehicles. They are combined together and form a battery pack. The battery pack can represent one of the most expensive and bulky assemblies in the context of most electric vehicles. This affects the cost of electric vehicles, making them unaffordable for many people. That is why it is important for companies to work to reduce the cost of battery packs. This is the main way to minimize the cost of electric vehicles for consumers.

Tesla has developed a structural battery pack

The vehicle structure is a critical component of efficiency and performance. Tesla is constantly working on its improvement. During Battery Day in 2020, the company announced it would improve the design of its vehicles using a new battery architecture, taking a truly radical approach to car parts manufacturing. On the same day, the 4680 battery cells were introduced.

Structural battery pack reduces production cost

With the new 4680 battery form factor, Tesla was able to minimize negative mass, thereby increasing battery density. The company was then able to place the battery more efficiently, further reducing the number of redundant structures within the package itself. The chassis of the car, consisting of two single-piece cast parts, front and rear, made it possible to place the battery in the middle. This greatly simplified production and made it more economical in terms of money and time. In addition, the seats are attached directly to the structural battery pack that serves as the cabin floor.

Tesla’s patent describes a system of impact attenuation in its structural battery pack

Since the battery pack is now also the floor of the car, the company needed to think hard about durability. In the patent “Impact attenuation for energy storage systems,” filed in January 2023, Tesla reveals ways to achieve this. The company describes that the battery pack can have or be integrated with a top surface. At the same time, it will necessarily include an impact attenuation layer. Such a layer may also include a first sub-layer and a second sub-layer.

The impact attenuation layer includes a first sub-layer of a primary material that has relatively larger strength attributes or stiffness than traditional plastic or polymer battery pack shell materials. The first impact attenuation layer may be made from, for example, steel, aluminum, alloy or other kinds of metallic material. The impact attenuation layer may also include a sub-layer of a second material that has a relatively larger energy absorption attribute. For example, various foams or plastics including but not limited to polypropylene, epoxy, polyurethane or other suitable alternatives.