Tesla’s Innovative Fastener Tech: Redefining Vehicle Durability and Efficiency

As Tesla continues to revolutionize the automotive industry, its latest breakthrough lies in a seemingly mundane yet crucial component: the fastener. This innovative step not only ensures the structural integrity of Tesla’s vehicles, such as the Cybertruck, but also transforms manufacturing processes.

Challenges of Galvanic Corrosion

Corrosion has long been the bane of automotive durability, particularly when combining different metals like stainless steel panels and traditional fasteners. This chemical reaction, known as galvanic corrosion, can lead to premature rust and degradation, particularly in vehicles exposed to the elements.

Tesla’s Cybertruck, with its iconic stainless steel exoskeleton, was facing this very challenge. The use of standard steel fasteners was out of the question due to their inability to withstand corrosion when coupled with stainless steel surfaces. While using stainless steel fasteners would seem a logical solution, the associated costs and mechanical inflexibility render this option unfeasible for mass production.

Revolutionary Non-Metal Fastener Solution

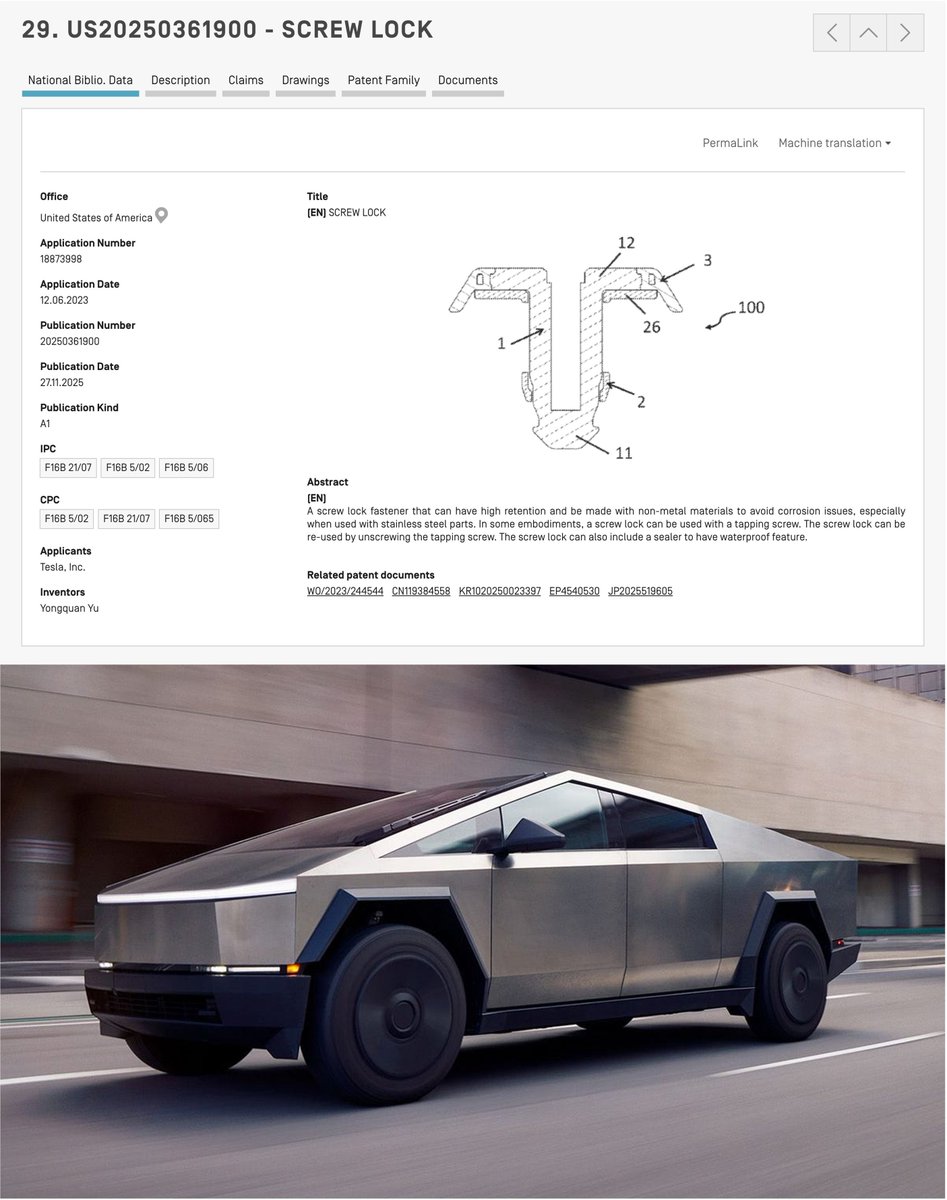

Tesla’s answer came in the form of a non-metal fastener system. Comprising a central rotating lock and flexible housing, this solution avoids the pitfalls of traditional metal fasteners entirely. Through a unique mechanical leverage system, the fasteners grip the vehicle panels with unprecedented strength without initiating corrosive reactions.

This breakthrough is underpinned by advanced polymer composites, notably glass fiber reinforced polyamide. These materials ensure that the fasteners maintain the requisite strength and durability, challenging the convention that only metals can provide structural robustness in vehicle assembly.

Efficiency in Manufacturing

Another significant advantage of Tesla’s fastener system is its alignment with the company’s visionary manufacturing strategy. Designed with efficiency in mind, these fasteners can be pre-assembled on parts before they reach the main assembly lines. This capability significantly reduces labor intensity and assembly time, contributing to Tesla’s competitive edge in rapid vehicle production.

The architectural design of these fasteners includes snap-fit joints that hold them securely during transport, minimizing the risk of misplacement or damage before installation. This approach not only enhances logistics but also ensures a streamlined assembly process.

Performance and Sustainability

Despite being categorized as ‘plastic’, these fasteners exhibit the endurance and strength to rival metal fasteners. They are engineered to withstand extreme conditions, offering retention forces that keep the vehicle’s body panels secured against challenges like high wind resistance and road vibrations.

Furthermore, these fasteners embody a commitment to sustainability. Unlike many other components that are single-use, Tesla’s fasteners are designed for multiple uses. They can be easily removed and reused, facilitating vehicle maintenance and reducing environmental impact through lower waste generation.

Future Prospects for Tesla

This innovation extends beyond simple component improvement. It represents a strategic leap forward for Tesla, particularly in advancing its modular “Unboxed” manufacturing process, which is pivotal to future models like the Robotaxi. By decoupling component assembly from the auto plant’s main production line, Tesla maximizes efficiency.

Financially, replacing costly metal components with advanced polymers offers significant cost savings, enabling Tesla to maintain a high standard of quality while preserving its margins. The thousands of fasteners on each vehicle cumulatively contribute to substantial cost reductions across large production volumes.

In summary, Tesla’s new fastener technology not only solves a critical engineering problem but also sets a new benchmark for innovation in automotive design and manufacturing. By tackling the nuances of material science with a groundbreaking approach, Tesla continues to define the future of sustainable and efficient vehicle production.

Source: Original Tweet